Electric vs. Gas-Powered Outdoor Cleaning Equipment: The Future of Municipal Maintenance

As cities worldwide grapple with climate commitments and noise pollution regulations, the debate between electric and gas-powered outdoor cleaning equipment has moved from environmental circles to city council chambers. This comprehensive analysis examines why the transition is happening slowly, what barriers municipalities face, and which cities are leading the charge toward a cleaner, quieter future.

The Noise Pollution Crisis: A Hidden Health Hazard

When most people think about outdoor cleaning equipment, they picture leaf blowers, street sweepers, and vacuum cleaners maintaining our public spaces. What they don't often consider is the invisible assault these machines wage on our hearing and mental health. Gas-powered equipment typically operates at 90-110 decibels—equivalent to standing next to a chainsaw or attending a rock concert without ear protection.

The World Health Organization identifies prolonged exposure to noise levels above 70 decibels as harmful, causing stress, sleep disturbance, and cardiovascular issues. Municipal workers operating gas-powered equipment face these levels daily, often for 6-8 hour shifts. Residents living near parks, schools, and commercial districts endure intermittent but regular exposure that disrupts work, education, and quality of life.

Electric alternatives operate at 60-75 decibels—comparable to normal conversation or background music. This 30-40 decibel reduction represents a dramatic improvement in worker safety and community comfort. Cities that have transitioned report fewer noise complaints, improved worker satisfaction, and enhanced quality of life in residential areas adjacent to maintenance operations.

The economic implications extend beyond health. Noise pollution reduces property values, with studies showing homes near high-noise zones selling for 5-10% less than comparable properties in quieter areas. For municipalities, this translates to reduced tax revenue and diminished community appeal—factors that forward-thinking city planners increasingly consider when evaluating equipment purchases.

Carbon Emissions: The Environmental Imperative

The environmental case against gas-powered outdoor equipment is staggering. A single commercial-grade gas leaf blower operating for one hour produces emissions equivalent to driving a modern sedan 1,100 miles. Street sweepers and vacuum cleaners, with their larger engines and extended operation times, multiply this impact significantly.

Key Emission Statistics

- •Gas-powered equipment accounts for 5% of U.S. air pollution despite representing less than 1% of engines

- •Two-stroke engines (common in older equipment) emit up to 30% of their fuel unburned

- •Electric equipment produces zero direct emissions and 60-80% fewer lifecycle emissions

- •Switching one municipal fleet can eliminate 15-25 tons of CO2 annually

The emissions profile extends beyond carbon dioxide. Gas engines release volatile organic compounds (VOCs), nitrogen oxides, and particulate matter—pollutants linked to respiratory disease, cancer, and premature death. These emissions concentrate in the breathing zone of operators and nearby residents, creating localized air quality hazards that disproportionately affect vulnerable populations including children, elderly residents, and those with pre-existing conditions.

Electric equipment eliminates direct emissions entirely. When powered by renewable energy sources—increasingly common as municipalities invest in solar and wind infrastructure—the environmental benefit becomes even more pronounced. Even when charged from fossil fuel-based grids, electric equipment's superior efficiency results in 60-80% fewer lifecycle emissions compared to gas alternatives.

For cities with climate action plans, transitioning outdoor cleaning equipment represents low-hanging fruit. Unlike infrastructure projects requiring years of planning and massive capital investment, equipment replacement can happen incrementally as existing machines reach end-of-life, allowing municipalities to demonstrate climate progress while managing budgets responsibly.

Operational Costs: The Total Cost of Ownership Analysis

The financial case for electric equipment challenges conventional wisdom. While purchase prices remain 20-40% higher than gas equivalents, total cost of ownership tells a dramatically different story. Municipal finance directors increasingly recognize that upfront cost represents only a fraction of equipment lifecycle expenses.

Fuel and Energy Costs

Gas-powered equipment consumes 0.5-2 gallons per hour depending on size and application. At current fuel prices, this translates to $2-8 per operating hour. Electric equipment costs $0.30-1.20 per hour in electricity—a 75-85% reduction in energy expenses. For a municipal fleet operating 2,000 hours annually, this difference amounts to $3,400-13,600 per machine per year.

Fuel price volatility adds hidden costs to gas equipment. Municipalities must budget conservatively, often overestimating fuel expenses to avoid mid-year shortfalls. Electric rates, typically locked through utility contracts, provide predictable costs that simplify budgeting and reduce financial risk.

Maintenance and Repair

Gas engines require regular oil changes, air filter replacements, spark plug maintenance, and carburetor adjustments. Annual maintenance costs average $800-1,500 per machine, not including major repairs. Electric motors, with fewer moving parts and no combustion process, require minimal maintenance—primarily battery care and occasional bearing lubrication. Annual costs typically run $200-400, representing a 60-75% reduction.

Downtime costs compound maintenance expenses. Gas equipment averages 15-25 days out of service annually for repairs and maintenance. Electric equipment typically requires 3-7 days, allowing municipalities to maintain service levels with smaller fleets or redeploy workers to other tasks during peak seasons.

"After switching to electric equipment, our maintenance budget dropped 40% and our operators reported significantly less fatigue. The business case was clear within the first year."

— Michael Chen, Fleet Manager, Portland Parks Department

Hidden Costs and Benefits

Worker health costs rarely appear in equipment budgets but significantly impact municipal finances. Gas equipment exposure correlates with increased sick leave, workers' compensation claims, and long-term disability. Cities tracking these metrics report 20-30% reductions in health-related costs after transitioning to electric equipment.

Public perception benefits, while difficult to quantify, influence municipal decision-making. Cities using electric equipment report improved resident satisfaction, enhanced environmental reputation, and easier recruitment of environmentally conscious workers—factors that contribute to overall municipal effectiveness and community pride.

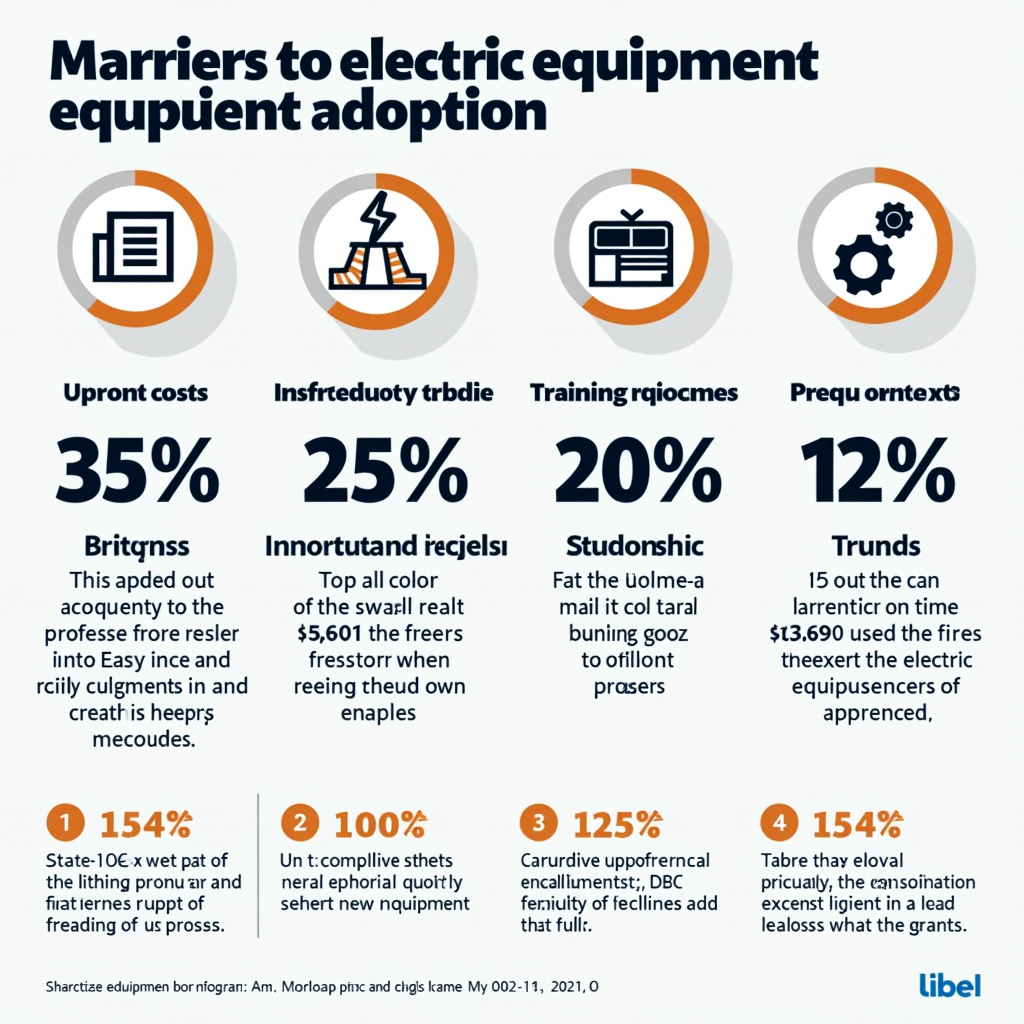

Barriers to Adoption: Why the Transition Remains Slow

Despite compelling environmental and financial arguments, electric equipment adoption proceeds gradually. Understanding these barriers helps municipalities develop strategies to overcome them and accelerate transition timelines.

Upfront Capital Costs

Municipal budgets operate on annual cycles with limited flexibility for capital investments. Electric equipment's higher purchase price—even when justified by lifecycle savings—requires budget reallocation or special appropriations that compete with other priorities. Smaller municipalities, operating with tight margins, find this barrier particularly challenging.

Grant programs and financing options help bridge this gap. Federal and state environmental agencies increasingly offer incentives for clean equipment purchases. Lease-to-own arrangements spread costs over multiple budget cycles, making transitions more manageable. However, awareness of these programs remains limited, and application processes can be complex and time-consuming.

Infrastructure and Charging Concerns

Electric equipment requires charging infrastructure that many municipal facilities lack. Installing charging stations involves electrical upgrades, permitting, and construction—processes that extend transition timelines and add costs. Facilities with limited electrical capacity may require service upgrades, further complicating implementation.

Battery runtime concerns persist despite technological improvements. Modern electric equipment operates 2-4 hours per charge—sufficient for most applications but requiring workflow adjustments for extended operations. Municipalities accustomed to refueling in minutes must adapt to charging schedules, maintain spare batteries, or stagger equipment deployment to ensure continuous operation.

Performance Skepticism and Cultural Resistance

Operators familiar with gas equipment often express skepticism about electric alternatives. Concerns about power, durability, and reliability reflect both legitimate performance questions and resistance to change. Early electric models, which sometimes underperformed compared to gas equivalents, reinforced these doubts.

Modern electric equipment matches or exceeds gas performance in most applications. However, changing perceptions requires demonstration programs, operator training, and patience. Municipalities that involve operators in equipment selection and provide hands-on experience report smoother transitions and higher satisfaction rates.

Procurement Process Challenges

Municipal procurement rules, designed to ensure fair competition and fiscal responsibility, sometimes hinder innovation adoption. Specifications written for gas equipment may inadvertently exclude electric alternatives. Lowest-bid requirements can favor cheaper gas equipment over higher-priced electric options, even when lifecycle costs favor electric.

Progressive municipalities address this by incorporating total cost of ownership into procurement criteria, weighting environmental factors, and developing specifications that accommodate both technologies. These changes require policy updates and staff training but enable more informed purchasing decisions that align with long-term municipal goals.

Success Stories: Cities Leading the Electric Revolution

While challenges exist, numerous municipalities have successfully transitioned to electric outdoor cleaning equipment, providing roadmaps for others to follow. These case studies demonstrate that with proper planning, stakeholder engagement, and commitment, the transition is both feasible and beneficial.

Case Study: Burlington, Vermont

Burlington began its transition in 2019 with a pilot program replacing 10 gas leaf blowers with electric alternatives. The city tracked noise complaints, operator satisfaction, and maintenance costs over 18 months. Results exceeded expectations: noise complaints dropped 65%, operators reported less fatigue and hearing protection needs, and maintenance costs fell 55%.

Building on this success, Burlington committed to full fleet electrification by 2025. The city secured state grants covering 40% of equipment costs and negotiated favorable lease terms for the remainder. By 2024, 80% of outdoor cleaning equipment was electric, with complete transition on track. Annual savings now exceed $45,000, with environmental benefits including elimination of 12 tons of CO2 emissions.

Key Success Factors

- ✓Started with pilot program to build evidence and operator buy-in

- ✓Secured grant funding to offset upfront costs

- ✓Involved operators in equipment selection and testing

- ✓Tracked and publicized results to maintain momentum

- ✓Developed charging infrastructure incrementally

Case Study: Pasadena, California

Pasadena took a comprehensive approach, transitioning not just leaf blowers but street sweepers and vacuum cleaners. The city partnered with equipment manufacturers to test prototypes and provide feedback, helping refine products for municipal applications. This collaboration resulted in equipment better suited to Pasadena's needs and strengthened relationships with suppliers.

The city invested $2.3 million in electric equipment and charging infrastructure between 2020 and 2024. While significant, this investment replaced aging gas equipment due for replacement anyway, minimizing incremental costs. Pasadena projects $380,000 in annual savings from reduced fuel, maintenance, and health costs—a 6-year payback period that improves as equipment ages and gas prices rise.

Community response has been overwhelmingly positive. Residents report quieter neighborhoods, particularly in early morning hours when maintenance often occurs. The city's environmental leadership has enhanced its reputation, attracting environmentally conscious businesses and residents. Pasadena now serves as a model for other California cities considering similar transitions.

Case Study: Washington, D.C.

The nation's capital faced unique challenges: extensive park systems, high-profile public spaces, and intense scrutiny of municipal spending. D.C.'s approach focused on high-visibility areas first, demonstrating electric equipment's capabilities in demanding applications. The National Mall, with its millions of annual visitors, became a showcase for quiet, clean maintenance operations.

D.C. leveraged federal sustainability initiatives to secure funding and technical support. The city established partnerships with universities to study health impacts, providing data that strengthened the case for expansion. By 2024, 60% of outdoor cleaning equipment was electric, with plans to reach 90% by 2027.

The transition has influenced federal policy, with several agencies adopting similar approaches for their facilities. D.C.'s success demonstrates that even large, complex municipalities can successfully transition, providing a template for other major cities.

The Path Forward: Accelerating the Transition

The evidence is clear: electric outdoor cleaning equipment offers superior environmental performance, lower lifecycle costs, and improved worker and community health. Yet the transition proceeds slowly, hindered by upfront costs, infrastructure requirements, and institutional inertia.

Accelerating adoption requires coordinated action from multiple stakeholders. Manufacturers must continue improving performance and reducing costs. Federal and state governments should expand grant programs and technical assistance. Municipalities need to update procurement policies, invest in charging infrastructure, and engage operators in transition planning.

Most importantly, cities must recognize that this transition represents not just an environmental imperative but an economic opportunity. The municipalities leading this change are realizing significant savings, improving worker satisfaction, and enhancing community quality of life. As technology improves and costs decline, the business case will only strengthen.

The future of municipal maintenance is electric, quiet, and clean. The question is not whether cities will transition, but how quickly they can overcome barriers and realize the benefits. For municipalities committed to sustainability, fiscal responsibility, and community health, the time to act is now.

Join the Clean Streets Revolution

Learn more about how innovative outdoor vacuum cleaner technology is helping cities transition to cleaner, quieter maintenance operations. Together, we can build a future where clean streets and healthy communities go hand in hand.